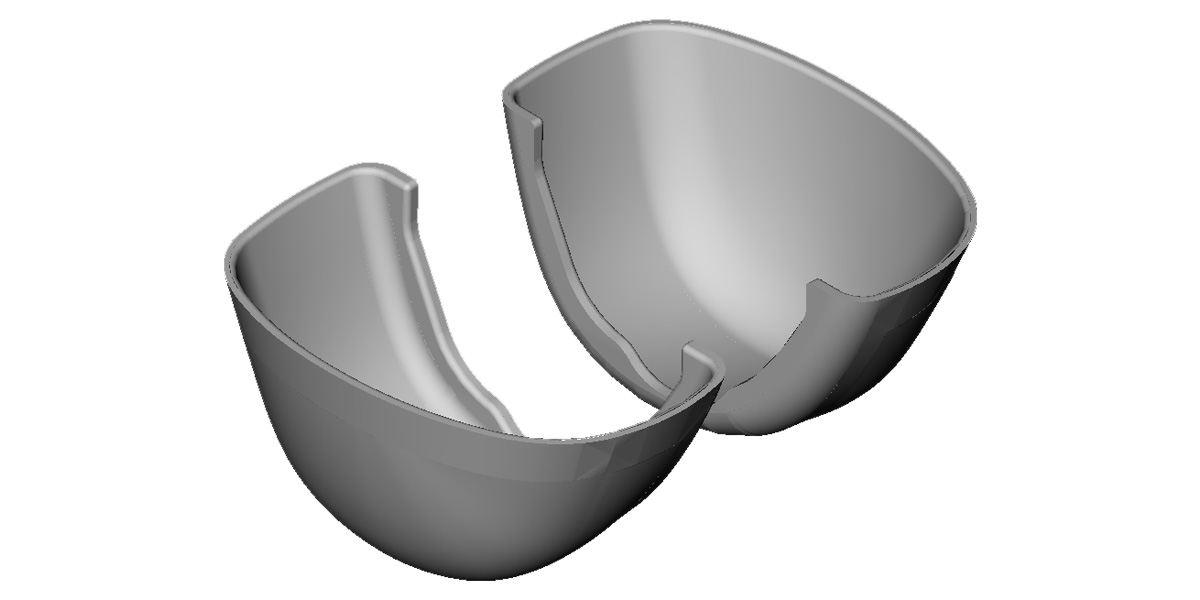

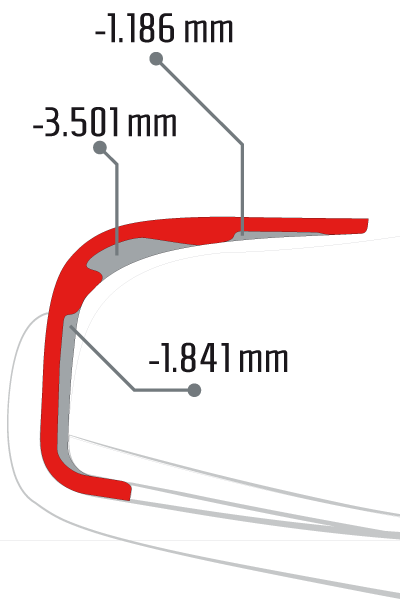

Toecap geometry

More

+ THIN

Using the topology and shape optimization process, areas that do not contribute to structural strength are identified.

More

+ LIGHT

In compliance with the required form the material is distributed in such a way that it satisfies the specific constraints and objectives required.

More

+ RESISTANT

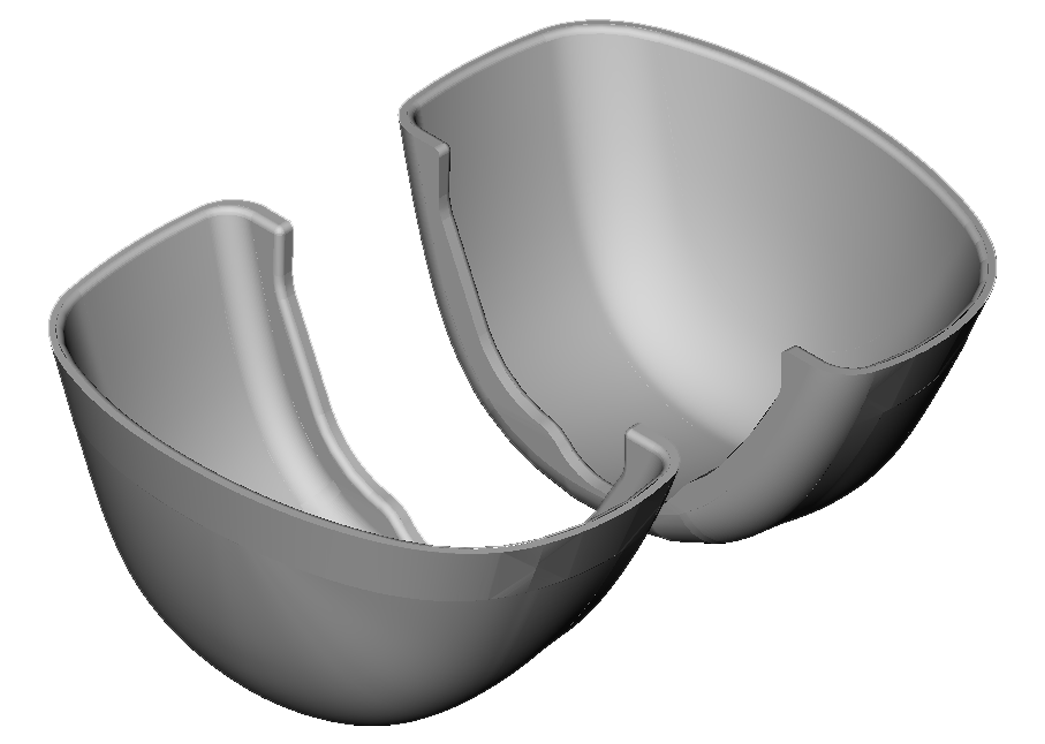

The new punctual geometry is well within the prescribed limits and there is no risk of breakage.

More

+ STRENGHT

Tensions and stress resistance are distributed better than before.

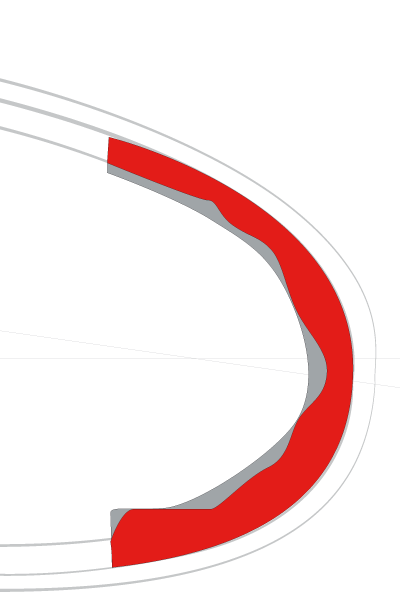

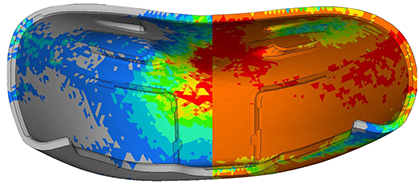

Plastic strain mapping of the section

During the Virtual Crash Test the plastic deformation is only superficial. Von Mises strength criterion mapping.

A unique light alloy casting technique

Application of a very high pressure on the material in the liquid state during the solidification phase.

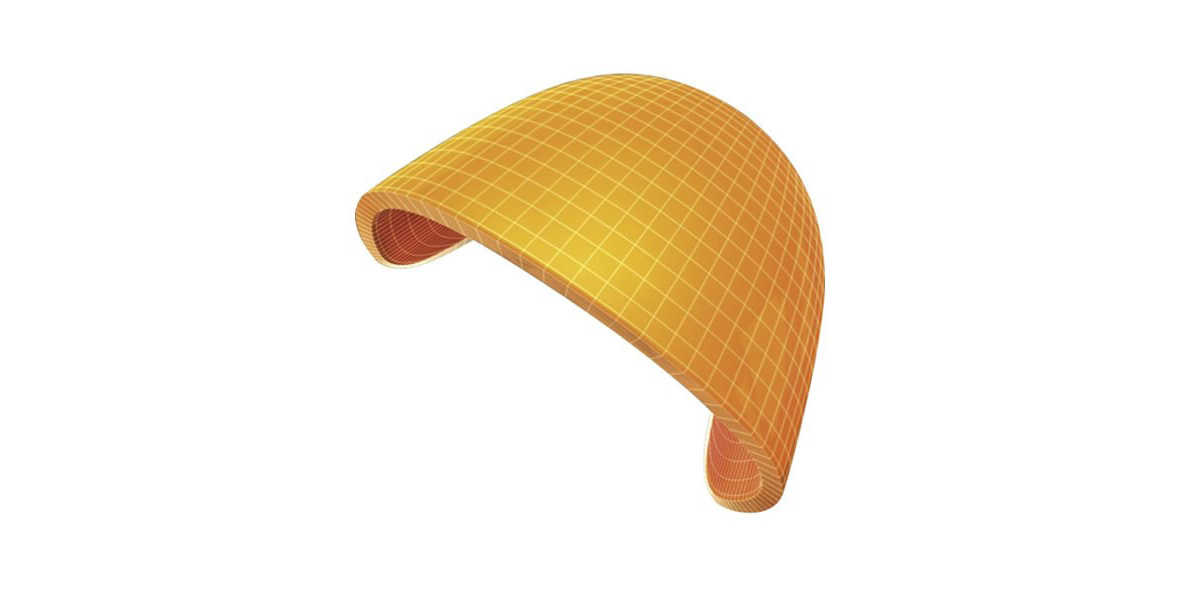

Weight reduction

![]()

With an average lower weight of 8 gr it is the best compromise between weight and performance.

– 8 gr (-14,3 %)

Our technology allows us to use material only where it is needed, we avoid unnecessary material costs and reduce weight.

Our lightest toe cap weighs 60 grams and our heaviest just 68 grams.

We produce all of our tips in-house and weigh them as soon as they are produced. Only tips with the right weight continue in the subsequent processes because the weight is one of the guarantees of the quality of the tip.

We guarantee the weight with a tolerance of +/- 3.5 grams.

With us you are more competitive

Do it right now

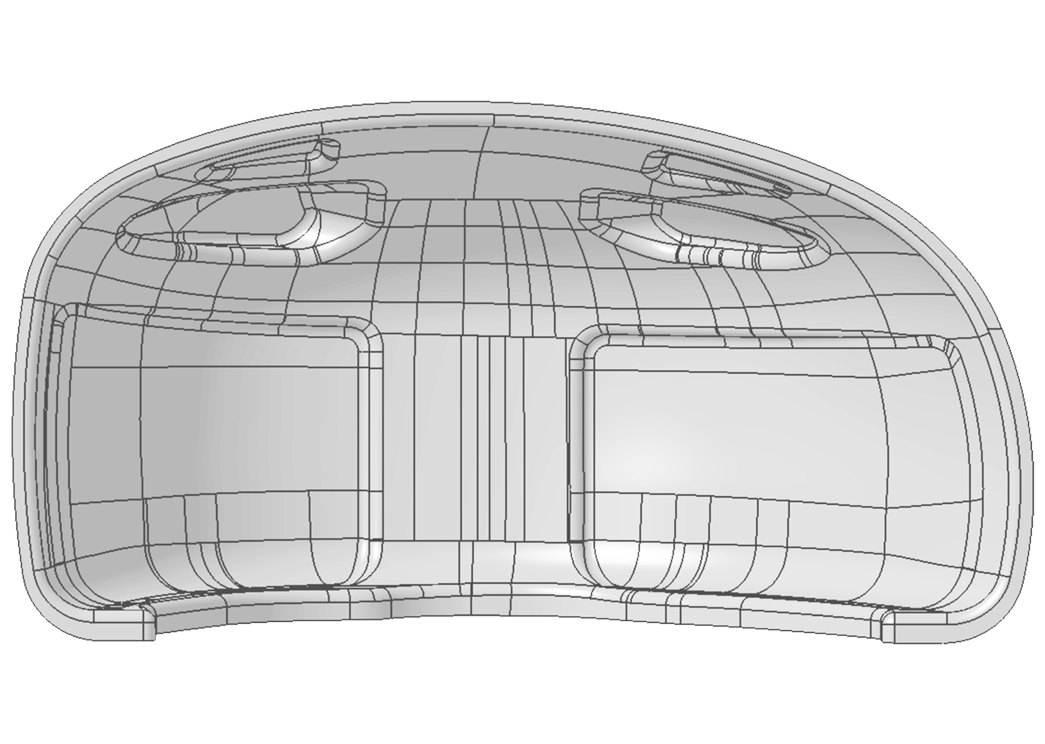

We prefer to get it right right away and not waste time and resources with lots of practice tests. This is why we design the tips with CAD and check them with FEM technology before building the mould. We simulate the resistance of the tip and if necessary we modify it to have the ideal performance.

Our moulds

We build our molds only with high quality steel and we test them directly in production to be sure of the production capacity. Once the production batch is finished, we check all the moulds, clean them and, if necessary, overhaul them with our specialized personnel.

Primary aluminum alloy

We internally produce the aluminum alloy only with primary aluminium. We chemically analyze every batch of aluminum alloy produced in our laboratory. Of course we keep the analysis data for many years.

We are the only ones to produce even small sizes, women too can have safe and light shoes, to wear even in the office. Our toe caps are 2x lighter than steel and less bulky than plastic but are just as sturdy.

We have 4 types of ferrules and sizes from 5 to 12, it’s easy for you to choose the right ferrule with our drawings and samples.